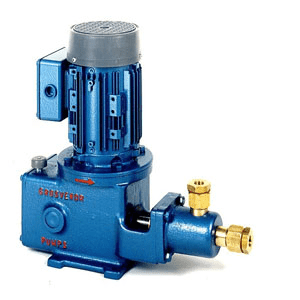

Piston Pumps

Delivering up to 11,365 litres per hour at up to 26 bar pressure

On this page

- About

- Typical applications

- Explore our range

- Custom piston pumps

- FAQs

Piston Pumps are positive displacement pumps, they do not use centrifugal force like centrifugal pumps They actively displace liquids utilizing the piston. The piston is fed straight into a cylinder with a stroke movement; the cylinder is sealed with a valve at the inlet and outlet. During the suction phase, the piston moves out of the pump housing; in the process, the inlet valve opens and the liquid flows into the cylinder. With the conveying movement, the piston moves back into the housing; the outlet valve opens, and the fluid is moved out of the pump.

While the operating principle of the piston pump is similar to that of the plunger pump, they do function differently. Piston pumps have an oscillating seal that moves with the piston, plunger pumps however, have a fixed seal through which the plunger moves.

The Grosvenor Piston Pump Range delivers up to 11365 litres per hour and up to 26 bar pressure. The combinations of bore, stroke and gear ratio outputs suit a wide range of applications. A pulsation damper is fitted to all sizes of pump as standard.

Our Piston pumps are used to move liquids or compressed gasses. They also pump viscous media and materials containing solid particles. With their wide pressure range, piston pumps are able to reach high pressures which can be controlled without impacting the flow rate.

Their continuous rate of discharge ensures the movement of viscous fluids, high gas volumes and solids throughout machinery. They are able to move fluids, regardless of viscosity. It is an incredibly efficient, long lasting piece of equipment.

Our Piston Pumps present many advantages;

- Wide pressure range

- Force can be managed without moving flow rate.

- The rate of flow and Pressure changes has a small outcome on the act.

- Ability to pump thick fluids and abrasives.

Explore our range of piston pumps

Grosvenor stocks a range of standard base model diaphragm pumps on the shelf ready to go. Click to learn more or use the custom order form to talk to us about a custom solution.

Typical Applications for Piston Pumps Include:

- Latex paints

- Flame retardants

- Thick coating materials

- Zinc powder paints

- Iron mica paints

- Airless spraying fillers

- Corrosion protection

- Water-proofing of buildings

- Bitumen and bitumen-like coating materials

- Fabric adhesives

- Sealants

- Plasters (filled) and others.

- Paints and Varnishes

- Dispersion Paints

Grosvenor Pumps specialise in custom piston pumps

We have been building custom pumps for over 60 years

Grosvenor Pumps understands that every pumping application requires a different solution, tailored to the needs of the specific industries worldwide. We operate a flexible manufacturing & assembly facility that enable us to offer Bespoke services to our customers. With our modular design and manufacturing in house we can build unique systems that incorporate a range of different pump heads, gearboxes, motors, stroke adjusters and more.

Our team is ready to help you build your solution.

Piston Pump FAQs

Find some commonly asked questions about piston pumps. For anything else, do not hesitate to contact us.