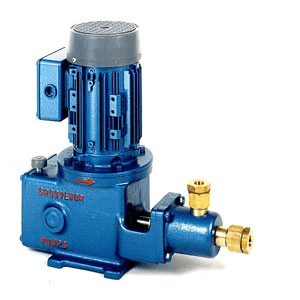

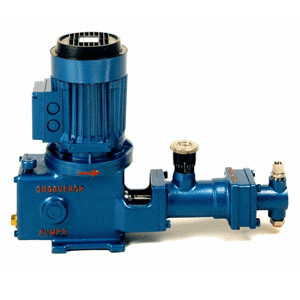

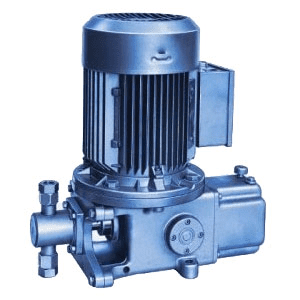

Plunger Pumps

Delivering up to 860 litres per hour at up to 175 bar pressure

On this page

- About

- Typical applications

- Explore our range

- Custom plunger pumps

- FAQs

The Plunger Pump functions like a piston pump, it sits within the oscillating positive displacement pump sector. However, instead of a piston, such pumps have one or several plungers as displacing element(s). The plunger is fed straight into a working chamber by a stroke movement, whereby the plunger is sealed off by a fixed seal. During intake, the plunger moves out of the working chamber, generating a suction effect, as the liquid to be conveyed streams into the pump through a suction valve. With the conveying movement, the plunger moves back, and the suction valve closes due to its own weight, a pressure valve opens, and the medium is conveyed out of the pump by the plunger.

The Grosvenor Plunger Pump Range delivers significant pressure through the utilization of high efficiency valves on the suction and discharge ports. This high pressure delivery results in an extremely accurate dosing solution.

Pump ends for the standard Plunger Pump are available with either 316 Stainless Steel or Cast Iron and Brass components. Valve assemblies are 316 Stainless Steel or Brass. The Valve Balls are available in 316 Stainless Steel, PTFE, Ceramic for Polypropylene. Valve Springs are 316 Stainless Steel and Gland Seals and O-Rings are Nitrile or PTFE. These pumps deliver up to 860 litres per hour at up to 175 bar pressure.

Grosvenor Plunger pumps can be used in a wide variety of applications, wherever liquid media has to be pumped at high pressure, they provide suitable solutions.

Given our sophisticated design, optimized material selection, flexible speed control and high precision manufacture, our plunger pumps can be used 24 hours a day without interruption. All material can be pumped in a liquid state. This can be water or oil at normal temperatures, but also hot oils and liquid gasses such as carbon dioxide and ammoniac. Due to their functional principle, plunger pumps are ideally suited for solutions with abrasives such as detergent slurries or coal mashes.

Typical Applications for Grosvenor Plunger Pumps Include:

- Process Technology for the Chemical and Pharmaceutical Industries

- Pressure Testing

- Urea Production

- Cleaning Applications

- Oil and Gas Production

- Coal Liquefaction

Explore our range of plunger pumps

Grosvenor stocks a range of standard base model plunger pumps on the shelf ready to go. Click to learn more or use the custom order form to talk to us about a custom solution.

Grosvenor Pumps specialise in custom plunger pumps

We have been building custom pumps for over 60 years

Grosvenor Pumps understands that every pumping application requires a different solution, tailored to the needs of the specific industries worldwide. We operate a flexible manufacturing & assembly facility that enable us to offer Bespoke services to our customers. With our modular design and manufacturing in house we can build unique systems that incorporate a range of different pump heads, gearboxes, motors, stroke adjusters and more.

Our team is ready to help you build your solution.

Plunger Pump FAQs

Find some commonly asked questions about plunger pumps. For anything else, do not hesitate to contact us.